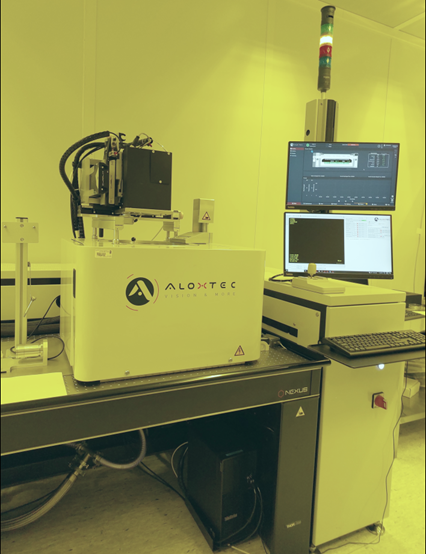

Vendor: ALOXTEC Vision & More, Model: ALOX 1.4

Contact: Nathan Suleymanov (073-3783291, nathan.sul@technion.ac.il)

ALOX 1.4 is an 8-inch furnace designed for wet thermal oxidation of III-V compound semiconductors, such as AlxGa1-xAs heterostructures. This oxidation phase is involved in VCSEL (Vertical Cavity Surface Emitting Laser) manufacturing and includes thermal oxidation of an Al-rich AlGaAs buried layer. The oxidation is proceeding laterally into a high Al concentration AlxGa1-xAs layer embedded in a heterostructure. The optical Vision system allows total control of the oxidized region shape and diameter. The oxidation is achieved by introducing DI water vapors into a heated reactor by a carrier gas (forming gas N2/ 5% H2).

Specifications:

- Up to 8” wafers : edge exclusion 5 mm

- Selective oxidation process

- Oxide aperture uniformity max – min < 0.8 µm

- Tight flow control of moisturized gas : 0,6 to 30 g/h

- Vacuum atmosphere : 20 mbar to 800 mbar absolute

- Stabilized temperature 350°C to 55 0°C

- Full control / supervision of machine

- Programming of recipes

- Automatic monitoring software to stop mesa oxidation at targeted aperture

- Run-to-run deviation σ < 0.2 μm