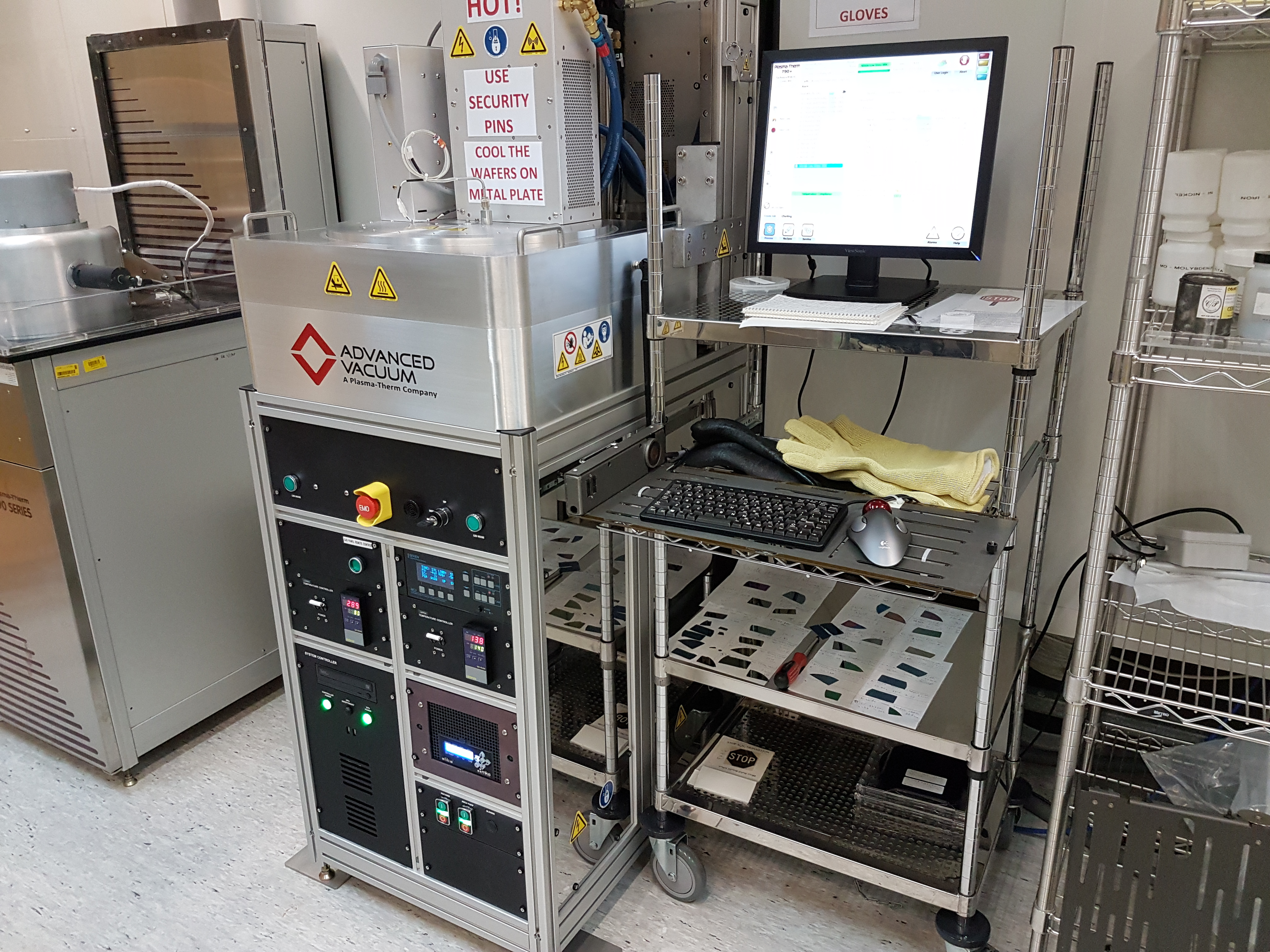

Vendor: Plasma-Therm, Model: Vision 410

Contact: Dr. Orna Ternyak (04-829-4204, ornater@technion.ac.il)

Plasma-Therm Vision 410 is a 16-inch diameter parallel plate, PC-controlled, PE-CVD system for deposition of dielectric films, such as SiO2, Si3N4, SiOxNy, low-stress Si3N4. Deposition is achieved by introducing reactant gases between parallel electrodes—a grounded electrode and an RF-energized electrode. The substrate, which is placed on the grounded electrode, is typically heated to 250°C – 300°C, depending on the specific film requirements. These films are usually used for interlayer electrical insulators, chemical passivation layers, hard mask for plasma etching, and anti-reflective coatings. The stress of the nitride can be tuned by adjusting the %He in the N2+He mixture without significant ion bombardment. SF6/N2O plasma is used to clean the chamber between depositions.

Specifications:

- High quality films with isothermally heated wall technology

- Direct loading (without load lock)

- Fully automatic and manual operation

- Available gases: SiH4 (5% in N2), NH3, N2O, N2, He, SF6

- Temperature of the chuck is controlled in the 80 ÷ 350°C temperature range

- 600 W RF @13.56MHz