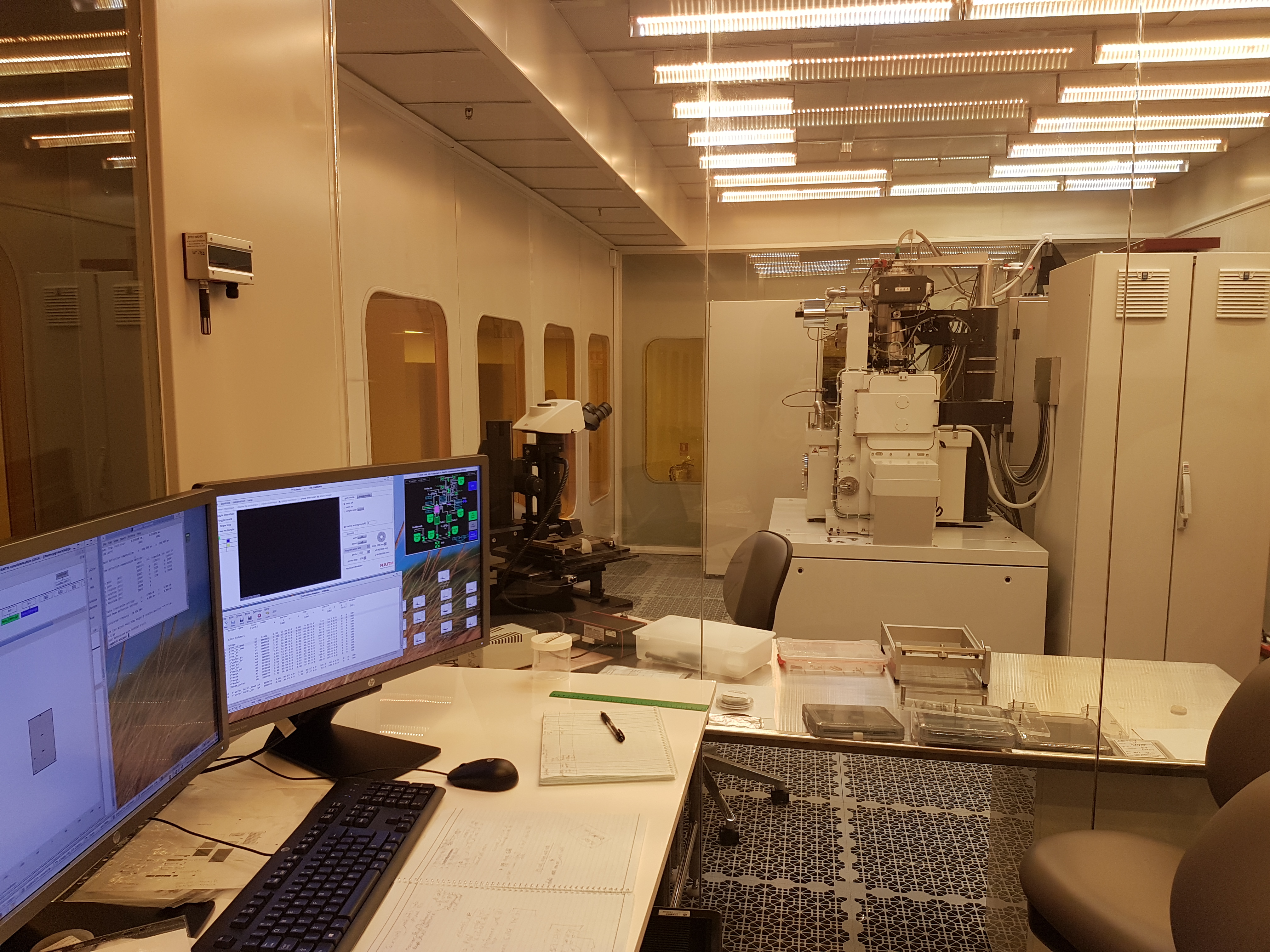

Vendor: Raith, Model: EBPG5200

Contact: Dr. Adi Goldner (04-829-3881, adigold@ef.technion.ac.il)

Electron beam lithography is a direct write technique for Micro and Nano patterning of substrate surface. In this process, CAD design is transferred, by moving high focused electron beam, into electron sensitive polymer resist, which was deposited by spin coat on a substrate surface just before the E-Beam exposure, and developed in specific solvents afterward. This process is usually an intermediate step in surface patterning, following by processes like lift-off or etching. Using E Beam Lithography, high resolution patterns which are below the optical lithography resolution limit, can be fabricated.

Raith EBPG5200 is a High Resolution, High Energy, fully automated, state of the art E-Beam lithography system, for direct write of different designs with a resolution down to 8nm line. The system is in operation since Nov. 2015.

Graduate students, Post doc candidates and other users from academy and Industry can get service or can be trained for independent use of the EBPG system.

Specifications:

- Possibility to work in two different acceleration voltages, 50kV and 100kV

- The system is using thermal filed emission source with a possibility to adjust specific beam current between 150pAmp to 200nAmp, with Gaussian beam diameter <5nm

- Exposure frequency is up to 50MHz

- Maximum beam deflection is 1mm, with stitching accuracy less than 20nm

- Stage has 210mm X & Y travel with position accuracy of 0.5nm

- Flexible marker recognition for multi-layer exposure with < ± 30nm registration accuracy

- External alignment microscopy with height meter

- GenISys Beamer software for data preparation (GPF formatter) and proximity correction

- The system has load lock with 9 different substrate holders for:

- Pieces from 5mmX5mm and up

- Wafers up to 200mm

- 4″, 5″ & 6″ mask plates

- Holders for thick substrates up to 6mm height

- Automatic cassette changer for continues exposure of several substrates in a row

- E-Beam Resists:

- Positive resists:

- PMMA (495, 950 & copolymer) with different density

- ZEP520

- CSAR62

- Negative resists:

- HSQ

- maN2403

- Positive resists: